Molded Fiberglass Grating:

Gratings & Covers

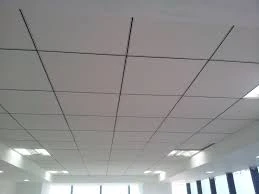

Weighing about 2.5 lbs square foot - about the same as 1/4-inch think flat sheet fiberglass plate, the grating over the flume is cut into sections so that it can be easily removed. Handholds are then either cut into each section or a bar of the grating is removed at one end of a grating section to allow an operator's gloved hand to lift the grating section out of the way.

Additionally, fiberglass tanks can be equipped with various accessories, such as pumps, valves, and level indicators, to improve their functionality and efficiency Additionally, fiberglass tanks can be equipped with various accessories, such as pumps, valves, and level indicators, to improve their functionality and efficiency

Additionally, fiberglass tanks can be equipped with various accessories, such as pumps, valves, and level indicators, to improve their functionality and efficiency Additionally, fiberglass tanks can be equipped with various accessories, such as pumps, valves, and level indicators, to improve their functionality and efficiency fiberglass storage tank.

fiberglass storage tank. If you don’t know fiberglass-reinforced grating, this stands for fiberglass-reinforced plastic. It’s considered to be a type of industrial flooring used in many kinds of construction projects.

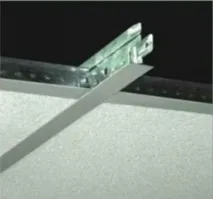

pultruded fiberglass grating. Unlike metal gratings, which require regular painting and cleaning to prevent corrosion, fiberglass grating is virtually maintenance-free. It is easy to clean with soap and water, and does not require any special coatings or treatments to maintain its integrity.

grating profiles cover an expansive range that covers requirements of the coal and iron ore industries, wine and beverage manufacturing, plant access walkways and heel-safe pedestrian access walkways to the current standards.

frp rectangular tube. This process ensures consistent quality, precise dimensions, and the ability to produce tubes in lengths up to several meters.

frp rectangular tube. This process ensures consistent quality, precise dimensions, and the ability to produce tubes in lengths up to several meters. Hengshui Jrain’s FRP products can be widely used on field of water treatment, wastewater treatment, odor control, etc.

grp products for steel smelting plant. Electrodes are used to conduct electricity into the furnace, heating the raw materials and facilitating the smelting process. Refractory bricks are used to line the furnace and other equipment, providing insulation and protection against the high temperatures and corrosive nature of the molten metal.

grp products for steel smelting plant. Electrodes are used to conduct electricity into the furnace, heating the raw materials and facilitating the smelting process. Refractory bricks are used to line the furnace and other equipment, providing insulation and protection against the high temperatures and corrosive nature of the molten metal. Molded Fiberglass Grating

2.Conductive fiberglass grating

Fibergalss grating itself is an insulator, non conductive, non thermal conductivity, but in some specific places, it also has a conductive requirements. The detailed operation method is to eliminate the damage of static charge inoculation in the rock layer with a thickness of about 3~5mm. The conductive grating also has same characteristics with traditional glass steel grille ,such as corrosion resistance, flame retardant,anti strike, skid resistance, light weight and practical in refinery and armaments manufacturing factory, high-tech industry, computer room, chemical plants, dry areas and underground mining operations.

Dual-pin connections are ideal for high-torque situations and can significantly improve the overall performance of the drill string Dual-pin connections are ideal for high-torque situations and can significantly improve the overall performance of the drill string

Dual-pin connections are ideal for high-torque situations and can significantly improve the overall performance of the drill string Dual-pin connections are ideal for high-torque situations and can significantly improve the overall performance of the drill string